Page 4 of 6

Re: Building a shop

Posted: Sat Feb 10, 2018 1:33 am

by John Whitley

Here’s the Misumi angle extrusion:

And a screengrab of the in-progress CAD model:

This will be attached to a VSC Tools Euro style T-square. The clamps secure the rip fence, a length of machined 40x80mm extrusion. Loosening the clamps allows the fence to slide fore/aft.

Re: Building a shop

Posted: Sat Feb 10, 2018 9:36 am

by Chris Hall

That's a nice looking extrusion!!

Re: Building a shop

Posted: Sat Feb 10, 2018 3:50 pm

by John Whitley

Chris Hall wrote: ↑Sat Feb 10, 2018 9:36 am

That's a nice looking extrusion!!

It really is! It looked “adequate” in CAD, but was so nice when I first had it in hand. I’ve never been briefly mesmerized by aluminum extrusion before.

All in all, the rip fence project is going to go a ways towards giving this saw a “Millenium Falcon” feel: a bit cobbled together, but can do the Kessel run in 12 parsecs.

Re: Building a shop

Posted: Sat Feb 10, 2018 5:17 pm

by Brian

Wow, that is nice!

Re: Building a shop

Posted: Fri Mar 09, 2018 8:52 pm

by John Whitley

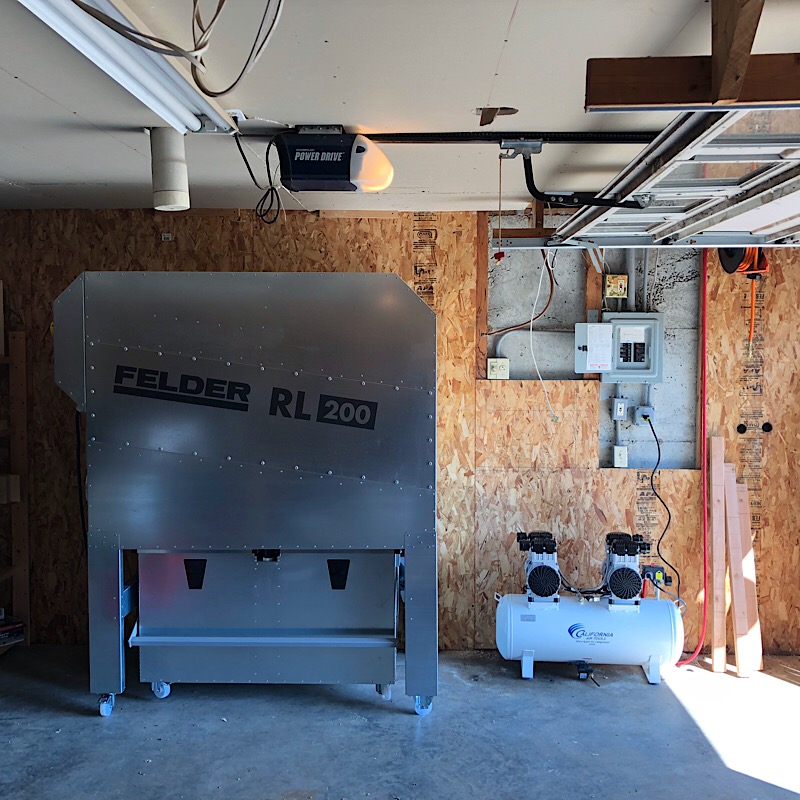

A brief update: I’ve finally settled on a dust collector, and have it on order. The shop’s low ceiling turned out to be a big challenge. A cyclone of any reasonable CFM capacity either wouldn’t fit, or required significant compromises to install. I’d considered building an enclosure outside, but that turned out to be prohibitively expensive due to the need for excavation and a retaining wall in the suitable location. I ended up going with a Felder collector, which fits neatly into the shop and has good inbuilt noise abatement.

Re: Building a shop

Posted: Fri Mar 23, 2018 12:15 pm

by John Whitley

A side project finished up yesterday: I added dust collection directly under the table of my bandsaw. Someone On The Internet had the good idea of cutting 2.5" pipe into a custom shroud around the lower bearing assembly. I took that idea and changed the mounting system by adding a 3D printed part that neatly handles the 30 degree angle between the shroud and the bandsaw. After I received the part, it was straightforward to fabricate a wood mounting block that correctly positions the shroud around the bearing assembly. (Achievement unlocked: I have now freehand drilled and tapped cast iron!) Two socket cap screws connect the shroud to inserts in the mounting block, allowing for fairly easy access, e.g. for blade changes.

And now for "pics or it didn't happen". Here's the overview shot. An ABS repair coupling was epoxied to the black 3D-printed mounting block, creating an adjustable mount for the ABS shroud pipe. A #8 screw on the far side of the coupling keeps the shroud pipe in place.

Top view. The shroud gets right up around the blade and bearings, but without interference:

Fully assembled:

Re: Building a shop

Posted: Fri Mar 23, 2018 4:07 pm

by John Whitley

A footnote to the prior post: in a few test cuts, there is now zero visible dust anywhere on or inside the bandsaw afterwards. Encouraging, given that previously any kind of cut started building a pile of sawdust on the base cabinet.

Re: Building a shop

Posted: Mon Mar 26, 2018 6:49 pm

by Brian

Wow, that’s awesome!

Re: Building a shop

Posted: Tue Mar 27, 2018 6:45 am

by Chris Hall

That is a clever idea.

Re: Building a shop

Posted: Thu Sep 06, 2018 11:37 pm

by John Whitley

Well, this happened today:

- IMG_06.jpeg (239.86 KiB) Viewed 6984 times

A bit of help from a friend through a pretty straightforward uncrating process and voila:

- IMG_0114.jpg (186.89 KiB) Viewed 6983 times

That was probably about a year’s worth of plotting and planning, to sort out what would work inside or adjacent to the space, then finally ordering and waiting for delivery.

Next stop is the electrical work, including three phase power, a reworked sub panel, and some additional outlets. Semi-parallel with that will be the final ducting design and install. The basic plan is set, which has one straight shot for the ducting main running across the shop, with a bit of machine layout work necessary to place the wyes correctly.