Page 1 of 2

Anvil Rework

Posted: Fri Jul 17, 2015 9:07 am

by Brian

I dropped my anvil off at the machinist for cleaning, they will remove all of the many years of crud. However since I worked for the machinist for many years he will outright refuse to do anything he knows I can do. He recommended me a cutter and told me to buy online. So in a week or two after the anvil returns I will put this to use;

Anvil Rework

Posted: Fri Jul 17, 2015 9:54 am

by Chris Hall

ooh! Shiny metal!

What's cutter called? What's the taper? Where did you get it from?

Re: Diving into Kanna

Posted: Fri Jul 17, 2015 11:14 am

by Brian

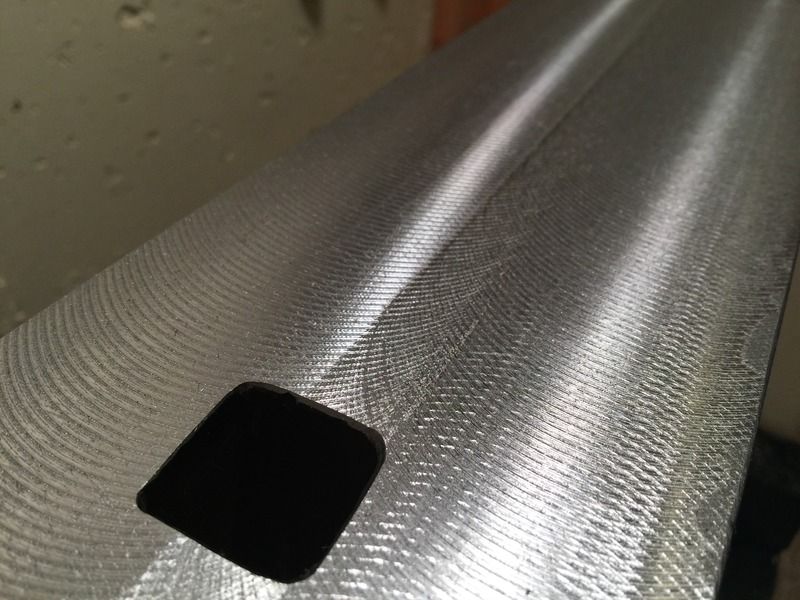

This is a carbide insert face mill. The shank is an R8 taper threaded for a 7/16 draw bar. I decided to go with round cutters rather than the other shapes as they're the best suited (that I'm aware of) for harder materials like steel. I bought it on ebay and it came straight from Hong Kong.

One the anvil is surfaced I plan to build an insert for the hardy hole out of aluminum for tapping out.

Re: Diving into Kanna

Posted: Wed Jul 22, 2015 6:19 pm

by Brian

Taking .010" per pass at 85 rpms.

I ran out before taking final pictures but it's all cleaned up. My father wants to work on it a bit and put a good paint job. Works for me

Last pass was .002"

Runout on this bit in this machine is .001". I suspect a good portion of that is in the taper.

Anvil Rework

Posted: Wed Jul 22, 2015 10:42 pm

by Chris Pyle

Brian wrote:Taking .010" per pass at 85 rpms.

I ran out before taking final pictures but it's all cleaned up. My father wants to work on it a bit and put a good paint job. Works for me

Last pass was .002"

Runout on this bit in this machine is .001". I suspect a good portion of that is in the taper.

Nice work Brian. People charge a fairly hefty sum for anvils around here. Excited to see how this one comes out.

Re: Diving into Kanna

Posted: Thu Jul 23, 2015 8:13 am

by Brian

Indeed, I've seen $2-$3 per pound for a really nice one. This one is a great anvil, but had been wailed on by highschoolers for about 50 years, badly swayback and with a nice concavity in the center and chipped up edges....all but one bit of damage has been removed.

I've been debating wether I will fully polish the surface, it might be helpful for certain fine work.

Re: Anvil Rework

Posted: Fri Jul 24, 2015 7:55 am

by Chris Hall

What do you think of the surface quality from the new cutter?

Re: Anvil Rework

Posted: Fri Jul 24, 2015 9:24 am

by Brian

Compared to pointed cutters I like the round. It cut without galling and left a textured finish that looks like it could be easily taken to the next degree of finish.

Once I get it home I'll take a close up photo of the result before I put any additional work into it. Funny enough I thought I was really running this bit to the extreme end and I've come to find out there is a lot more to go in terms of cutting speed. So next time I run it I plan to bump the cutting speed up and possibly the feed rate.

Re: Anvil Rework

Posted: Wed Jul 29, 2015 11:46 pm

by Brian

Re: Anvil Rework

Posted: Fri Jul 31, 2015 8:12 am

by Brian

Onto the polishing stage of the face....oh what fun. I'll post a picture once I've made some worthwhile progress.