Thank you, I appreciate the guidelines.

These are really awesome joints, they really come together to make a strong connection and back apart again with ease. I won't likely ever need to break down this bed, but it's nice to have the ability to at some point, less the wedge tenons which I have planned for the outside corners. Those I plan to reversible glue so that it can be broken down at some point if absolutely necessary.

Bed Build

- Brian

- Deshi

Post

Re: Bed Build

Chris, hope you don't mind, I would like to run this tusk tenon layout past you and get your thoughts;

I've not done these style of tusk tenons previously, instead I've done the upright through tenon into post with wedging key type.

I've laid them out with 1/2" thick tenons which will be wedged rather than pinned.

I've not done these style of tusk tenons previously, instead I've done the upright through tenon into post with wedging key type.

I've laid them out with 1/2" thick tenons which will be wedged rather than pinned.

- Chris Hall

- Site Admin

- Contact:

- Location: Greenfield, Massachusetts

Post

Re: Bed Build

Tenon layout looks good, and I'd be curious about the mortise that goes along with it - you mention that this will be traversing through a post?

- Brian

- Deshi

Post

Re: Bed Build

Thanks Chris,

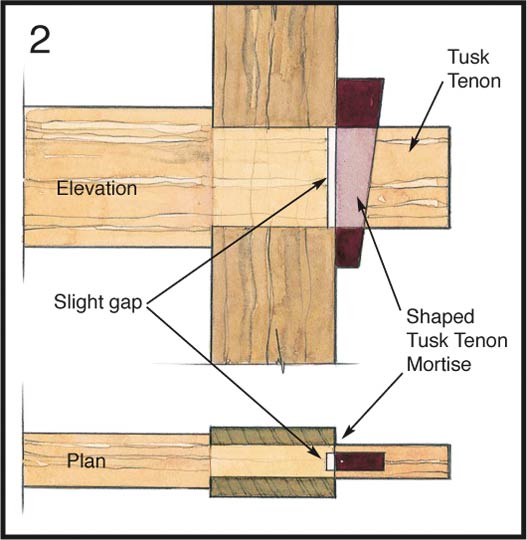

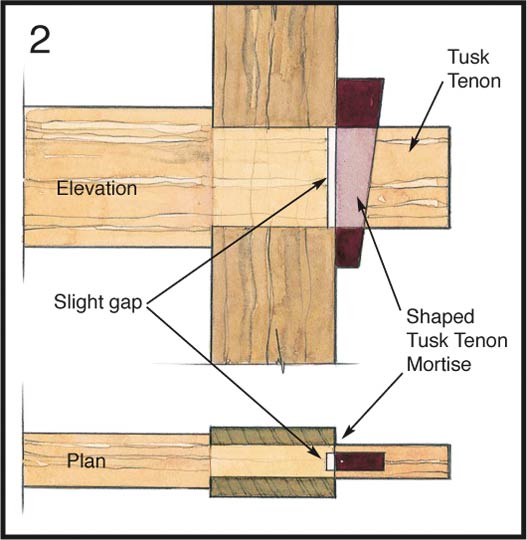

I mean to say that in previous examples I've only done this sort of assembly;

Whereas this one I have this planned;

With the minor exception that the tenon will be made through the beam, will be kerfed and then fitted with wedges. Not as easily reversible as a pin, but in this case I feel that 8/4 doesnt leave much meat for a pin. Maybe I'm worrying about nothing, but the short grain after the pin would be about 1".

I mean to say that in previous examples I've only done this sort of assembly;

Whereas this one I have this planned;

With the minor exception that the tenon will be made through the beam, will be kerfed and then fitted with wedges. Not as easily reversible as a pin, but in this case I feel that 8/4 doesnt leave much meat for a pin. Maybe I'm worrying about nothing, but the short grain after the pin would be about 1".

- Chris Hall

- Site Admin

- Contact:

- Location: Greenfield, Massachusetts

Post

Re: Bed Build

The idea with a tusk tenon (and the top illustration in the preceding post is not a tusk tenon in my view) is that the tenon inserts through the neutral axis of the receiving member. The sloped abutment above the tenon means that material is not removed from the critical upper surface of the receiving member, and the housed projection below the tenon means that the lower arris of the receiving member is not disturbed.

I would be curious to see how you have designed the mortise in the receiving member, as, based on the tusk tenon layout you showed a few posts back, the receiving member should be a significantly taller section of wood.

I would be curious to see how you have designed the mortise in the receiving member, as, based on the tusk tenon layout you showed a few posts back, the receiving member should be a significantly taller section of wood.

Depends upon section sizes and the size of the pin you intend to use...Not as easily reversible as a pin, but in this case I feel that 8/4 doesn't leave much meat for a pin. Maybe I'm worrying about nothing, but the short grain after the pin would be about 1"

- Brian

- Deshi

Post

Re: Bed Build

Ahh I see. The the receiving section will be the same height, so with that in mind what changes would you make to the layout?

I presume a square tapered pin would be the easiest to remove, I'd probably shoot for 1/2" square with a slight taper (maybe 1/16" over the 3" length).

I presume a square tapered pin would be the easiest to remove, I'd probably shoot for 1/2" square with a slight taper (maybe 1/16" over the 3" length).

- Chris Hall

- Site Admin

- Contact:

- Location: Greenfield, Massachusetts

Post

Re: Bed Build

If the receiving member is the same section height as the tenoned piece, then the tenon must be centered to the axis, ditto for the mortise. As a result, the housing below the tenon can be extended downward.

The section is 3" deep, however looks to be about 1.5" wide. A 0.5" peg would be way too large. Probably 5/16" max I would say is about right. You need 1.5 times peg diameter on each side of the peg, and at least 3x peg diameter beyond the peg.I presume a square tapered pin would be the easiest to remove, I'd probably shoot for 1/2" square with a slight taper (maybe 1/16" over the 3" length).

- Brian

- Deshi

Post

Re: Bed Build

Thanks Chris, I'll make some changes to the layout. I appreciate the guidelines on this as well, the thickness of these pieces is 1.75", so based on that I'm looking at about .25" if I do a peg.

I think I would prefer a peg, as I can then do a blind mortise. This bed will have wedged tenons at the corner joints, so that is plenty in view, IMO.

I think I would prefer a peg, as I can then do a blind mortise. This bed will have wedged tenons at the corner joints, so that is plenty in view, IMO.

- Chris Hall

- Site Admin

- Contact:

- Location: Greenfield, Massachusetts

Post

Re: Bed Build

That looks fine. Allowing at least 1/16" extra depth in the mortise beyond the tenon, will have about 3/16" material left in the floor of the mortise, if my estimate of your dimensions is correct.

Who is online

Users browsing this forum: No registered users and 15 guests